OPTION 1: Borrow drapery from the Theatre Department, and hang it along both the north and south walls. Make sure they do not smell as foul as the drapery used during our experiment.

OPTION 2: Use a 1-inch thick application of k-13, a spray-on acoustical treatment manufactured by International Cellulose Corporation, over the existing "acoustical plaster." Estimated cost, including materials and installation: $4,000.

OPTION 3: Use a 1-1/2 inch thick application of k-13, a spray-on acoustical treatment manufactured by International Cellulose Corporation, over the existing "acoustical plaster." This option will provide an additional reduction in low-frequency reverberation over Option 1. Estimated cost, including materials and installation: $5,000.

OPTION 4: Install 750 s.f. of 2" thick acoustical wall panels, such as the Ap200 panels manufactured by Decoustics, over the existing north and south walls. These panels should be distributed as evenly as possible. In addition, replace the existing acoustical panels on the rear wall (approximately 150 s.f.) with 1" thick acoustical wall panels, such as the Ap100 also manufactured by Decoustics. If desired, impact-resistant panels may be used. Estimated cost, including materials and installation: $6,300.

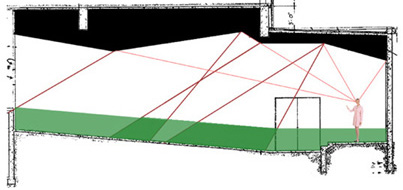

The current ceiling configuration has some problems. As discussed earlier, the ceiling planes do not allow reflections to reach all audience areas. Notably, the lighting soffit above the front of the platform is contrary to any desired acoustical effects, since it blocks critical reflection paths to the audience and reflects sound back toward the speaker and the stage area. Modifying the ceiling would be a significant undertaking, which is one reason we have not focused on that as a the primary means of improving the acoustical environment. On the one hand, with the room as small and reverberant as it is, it is not as necessary for the ceiling to disperse reflections evenly to all audience areas as it would be in a larger lecture hall or auditorium. The "acoustical plaster" currently on the ceiling was intended to make it absrptive, which means that the angles of the ceiling planes are mostly meaningless, as the ceiling will absorb sound and not reflect it. Treatment options 2 and 3, above, include making the ceiling more absorptive, in which case it would not be beneficial to reconfigure the ceiling. Option 4, however, includes adding acoustically absorptive material to the walls, in which case ideally the ceiling should be reconfigured to provide even reflections to the entire audience. We recommend the following ceiling configuration as way to achieve this:

Ray Diagram Showing Even Coverage of all Audience Areas

- Steve Hildebrant, Lawrence Hall Building Manager

- Janet Rose, University of Oregon Theatre Department

- Laura Schwope, Graduate Student, University of Oregon

- Lonny Anderson, Gratuate Teaching Fellow, ECS-II, University of Oregon

Information was obtained from the following sources:

- Mechanical and Electrical Equipment for Buildings, 8th Edition, Benjamin Stein and John S. Reynolds, John Wiley & Sons, Inc., 1992.

- Environmental Control Systems II website, /~akwok/ecs2S00/115-draw.htm

The cost opinions listed herein are based on previous experience, and should not be taken as quotes. They are opinions only. Manufacturers were not contacted to present quotations specific to this project. For more information, contact Chad D. Weltzin, P.E.